July 20, 2020

Copper, a metal commonly used throughout history for its antibacterial properties, is being utilized by researchers at IUPUI’s Integrated Nanosystems Development Institute to solve a problem very relevant today: making reusable face masks safer and more comfortable for daily use.

"We wondered how we could use our existing technology to turn something used in ancient times, like copper, into protection against COVID-19," said Mangilal Agarwal, director of the Integrated Nanosystems Development Institute and professor of mechanical and energy engineering. "Any virus sitting on the surface that comes in contact with copper will be killed because of the antiviral properties."

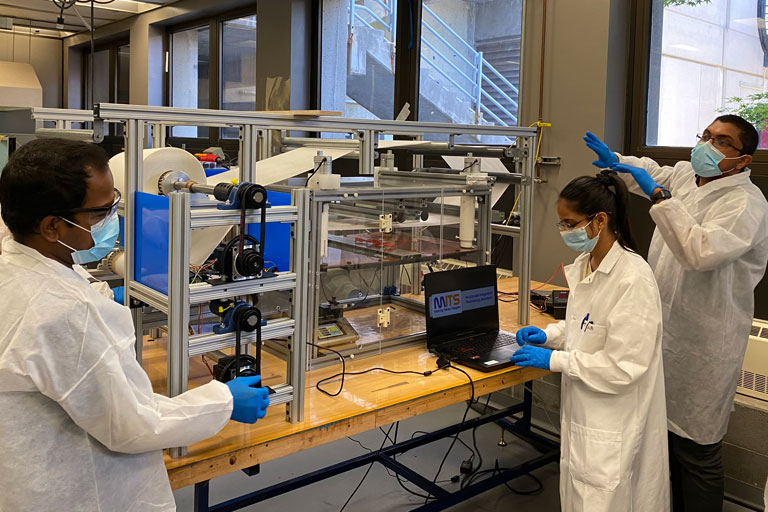

Agarwal and Hamid Dalir, associate professor, are applying a patented technology developed at IUPUI to manufacture reusable face masks using copper, a metal often used in the production of high-touch objects like doorknobs and handles. Their goal is to improve filter performance by trapping and disabling airborne virus particles.

“These masks have copper oxide applied at the nano level and would offer ultimate protection against virus risks like COVID-19,” Agarwal said. “Some cloth masks allow the small airborne particles to pass through, but with our technology, it would be close to 100% proof that you have the capability incorporated in the mask to deactivate the virus and improve filter performance.”

The technology – initially developed at IUPUI to make composite materials cheaper, lighter and stronger using nanomaterials – could be used to coat household masks with a layer of fabric protection inlaid with copper nanoparticles that disable virus particles as they reach the surface. The general public would be able to wear a reusable mask that offers the same superior level of protection as masks worn by health care providers, such as N95 masks.

“To make any fabric into a mask or filter, we have to provide the nanostructure, and we can put that nanostructure on a roll-to-roll printing machine with the fibers at nanoscale,” Agarwal said. “We are using electrospinning, using the electric field to spray the nanofibers onto the fabric.”

Agarwal and Dalir disclosed their technology to the Indiana University Innovation and Commercialization Office, and are looking to commercialize it through their startup. They plan to work with local companies manufacturing COVID-19 supplies under the Defense Protection Act.

Description of the video:

[Music plays]

[Man wearing a white shirt appears on screen]

At Integrated Nanosystems

[Photo of IUPUI campus appears]

Development Institute,

[Man wearing a white shirt reappears on screen]

[The words, Mangilal Agarwal, Director of Integrated Nanosystems Development Institute displayed at bottom of screen]

me and my colleague Dr. Hamid Dalir are working on making reusable

[Close-up of reusable face mask appears on screen]

material that can capture

[Mangilal reappears on screen]

and kill the virus.

[Close-up of a different face mask appears on screen]

Surgical masks can provide you protection

[Mangilal reappears on screen]

with larger particles,

[Video of a microscope in a lab appears]

but for a virus as small as 100 nanometer,

[Child sneezes on screen]

they are not very effective to capture all the

[COVID-19 particles appear on screen]

airborne virus particles.

[Electrospinning equipment appears on screen]

To code this layer, we are using electrospinning

[Close-up of electrospun fibers appear on screen]

technique that we have

[Mangilal reappears on screen]

developed here at IUPUI.

[Video of electrospinning machine appears on screen]

It is similar to like spray painting.

[Women in lab coat points at diagrams of electrosprayed fabric on a white board]

[The words, Vidya Wable, Graduate Student displayed at bottom of screen]

These are the nylon nanofibers, and these are the copper nanoparticles.

[Close-up of the copper nanoparticles diagram appears on screen]

When we electrospin

[Close-up of the electrospinning machine appears]

and electrospray both

[Vidya reappears in front of the white board and diagrams]

simultaneously, it looks

[Vidya points to a diagram example]

like this. So nylon traps

[Vidya reappears in front of the white board and diagrams]

the viruses and copper kills the viruses.

[Two men in white lab, holding a reusable face mask, appear on screen]

Here you can see we have replaced the middle layer of the surgical mask,

[The words, Pias Kumar Biswas, INDI Research Assistant are displayed at bottom of screen]

and we have modified them with our current technology, which is electrospun nylon fiber and electrosprayed

[Video pans of diagrams of nylon fiber]

copper oxide nanoparticle. You can apply this coating on any other substrate,

[Electrospinning machine appears on screen]

HVAC filters at home or at commercial buildings, and also schools.

[Mangilal reappears on screen]

We are also collaborating with local companies

[Pias and colleague reappear on screen]

which are working on the Defense Protection Act to manufacture COVID-related

[Researcher uses a machine in the lab]

PPE. IU

[Video shows a closeup of a machine being used by researcher]

Commercialization Office has been tremendous help. Since we disclosed this technology to their office,

[Electrospinning machine appears on screen]

they have helped us to

[Mangilal reappears on screen]

figure out how to start a company,

[Video of a reusable face masks reappears on screen]

filing the patent last year. I think having a unit like ICO

[Video pans over the electrospinning machine]

can make this happen, to work

[Mangilal reappears on screen]

together, collaborate and succeed.

[Screen fades to black; the IU trident and the words Indiana University, research.impact.iu.edu/coronavirus appear against black screen.]

[Words fade out; music ends]

Beyond face masks, the technology can be applied to other methods for fighting COVID-19, such as HEPA filters found in HVAC systems. Without good filters, Agarwal said, airborne virus particles could circulate between indoor areas. By applying the copper material to the filters, there could be virus free air circulation in buildings and hospitals.

“Our technology is good for masks and filters because we are not changing the manufacturing process,” Dalir said. “We just get the rolls of the mask and filter, manufacture and enhance it with copper-coated fabric and then use it as it would be used conventionally.”

Their company, Multiscale Integrated Technology Solutions, was recently selected as one of five Hoosier startup winners of the Elevate Nexus Statewide Pitch Competition, a program designed to support Indiana startups.

“Elevate Nexus is being funded by a grant from the U.S. Economic Development Administration and the 21st Century Research and Technology Fund to help startups that have shown potential for commercialization to get connected with entrepreneurs to build on existing operational strategies," Dalir said. "What we're trying to do is raise the existing entrepreneurship support vehicles as well as attract investment in our startup at an earlier level so that we can have the opportunity to further grow and cultivate new investors as we de-risk our venture.”

The commercialization of their technology has the potential to greatly impact lives here in Indiana and around the world – providing a safe solution against the spread of COVID-19.